|

| First big snow of winter 2013! |

The appliqued prayer flags that I put in my front yard last July look amazing against this white backdrop.

|

| colorful flags contrast with white snow |

- Some tips and tools for moving looms

- A new power supply for those of us who are electronic

- A warping tip as seen on my CP recently

- Looking ahead to 2014

Moving Day

Since so many of you purchase used looms and face the seemingly monumental task of transporting your new/used loom across country, I thought a blog posting on this topic was in order. I consulted Eddie at the shop who crates and ships looms every week. First tip - I advise that you ask the seller not to take anything apart on the loom. It is helpful to see the loom set up before you take it apart to move it. Here is a list of helpful tools/supplies for moving your loom: |

| Some of the things you will need to move a loom...plus big muscles! |

- Camera to document what the loom looks like all set up. Also document how you took things apart.

- Old blankets, towels for padding

- Zip lock bags for small parts, marker to label the bags.

- Small screw driver for the collars on the treadle rod. Some of these collars require an Allen stye wrench. So you might be smart to bring a small Allen wrench kit.

- Fiberglass packing tape, blue painters tape (the kind that won't ruin wood).

- Rope or heavy cord.

- Silicone spray.

- Card Board and craft paper.

- Hammer and small metal rod.

| Loom all crated and ready to ship. |

|

| Loom all secured for travel. |

| |||

| Loosen collar that holds treadle bar in place. |

- Remove the beater.

- Remove the beams, front/cloth beam and back/warp beams. remember to bag and label the brake parts.

- Remove the treadles by taping out the rod that holds them in place. Before you tap out the rod, loosen the small collar that holds them in place. Use a hammer and a similar size metal rod to tap.

- Use Silicone spray if tapping out the rod is challenging.

Tapping out the treadle rod. - You can also remove the back beam at this rod if you want to.

- To remove the front breast beam you will need a 3/8" wrench to undo the bolt.

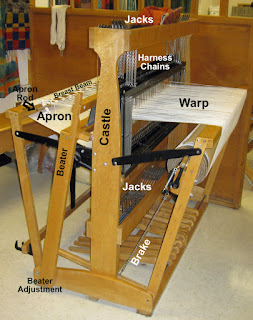

- The harnesses represent a lot of weight. So removing them is a good idea. But please understand that without the weight of the harnesses, the lamms, side wires and jacks are at risk of damage and bending. So you MUST secure the jacks in place prior to removing the harnesses.

- The best method to secure the jacks is to use Fiberglass tape and some craft paper or cardboard. Wrap the paper/car board around the cross pices of the castle to secure the jacks in pace. Wrap tightly with the tape. This should be done very tightly so that the jacks will remain in place once the harnesses are removed. Unfortunately I do not have a photo of this. I'd love to have one if anyone does this!

- Once the jacks are secure you can remove the harnesses by slipping them off the chains. Be sure to bag up any chains and S hooks that are loose.

- The rest of the loom is glued together. I recommend NEVER taking apart glued joints.

I would LOVE to get photos of your looms in transit, plus any tips/comments on this topic! Happy moving day! When I as in art school, my (now) husband and I moved 9 times in a year, our theme song was Moving Day by the Holy Modle Rounders. We got pretty good at moving looms!

Powering Up

About a year ago, the manufacturer for the power supply/loom control for all Macomber compu-dobby looms retired. I was dismayed...until John Acord appeared on the scene! John is a weaver and all round wizard with support for compu-dobby looms. |

| Flatwater Electronics power supply and loom control |

Here's what John says "A replacement control and power unit for the Air-dobby is now available. Two versions are available. 16-shaft and 32-shaft. Coming soon will be the version for the Electroinc Single Pedal. (electro-mechanical solenoid drive).

The new control box utilizes modern efficient components and power supply, significantly reducing the size. The box is not much bigger than a CD case.

Incorporated into the control are protection circuits to prevent damage to your loom in the case of solenoid failure or problems with wiring and connections. In addition, indicator lamps on the front help the weaver confirm operations of boththe loom and computer."

For more information visit Flatwater Electronics.

Threading the reed

I have described to a few of you how I set you the reed in a horizontal fashion to thread it. I do this for two reasons - it is better for my posture/back and it is all round easier to see and thread. I support the reed on two long lease sticks that run front to back on the loom. From this position it is easy to see the ends to thread and the reed slot that you are aiming for. I use a similar set up for my B model loom. |

| Threading the reed on a CP. |

| ||

| 56" ready to be dressed in blues! |

Looking ahead to 2014

Our Maine winter has not officially begun (Dec 21st), but I will tell you in is VERY cold, snowy and great time to be inside weaving!I am also dreaming about my trip to India in January. I will be away from January 11 to February 10th. I'm not sure what kind of Internet access I will have, but if I can I will post some photos and stories. Rest assured I will have much to share upon my return. If you are interested in ordering parts or looms, please contact Eddie at the shop. 207-363-2808 If you mention my name, I will happily receive credit for your purchase! Thanks!! If you order a loom through me I will give you a free copy of my Macomber Looms Manual!

As 2013 draws to a close, I find much to be grateful for, including each of you dear weavers. You are a special bunch, who deeply care about each other, willingly share information and support the best in each other.

Thanks for all your business this year. I am always happy to help you!

May the love and peace of the season light up your heart and home.

Namaste ~ Hindu for I honor the light in you ~ Sarah